|

Exploring unlimited possibilities untapped in raw materials

As electronic devices become smaller, more functionally advanced, and with higher added value, requirements for materials more diversified. To respond to various needs, we provide a variety of thick film materials.

The composition of Noritake Co., Limited's thick film materials The composition of Noritake Co., Limited's thick film materials

Conductive Pastes  |

|

Series

|

The use

|

| NP-1000 (Pt Paste) |

The electrode for sensor etc… |

| NP-2000 (Ag/Pt Paste) |

The electrode for Hybrid IC etc… |

| NP-3000 (Ag/Pd Paste) |

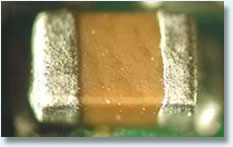

The inner and termination electrode for MLCC and C/R etc… |

| NP-4000 (Ag Paste) |

Practicable pastes lineup in the firing temperature range of 400~950℃. Possible to use as the electrode and Chip components etc… |

| NP-5000 (Au Paste) |

The electrode for Bonding |

| NP-6000 (Pd Paste) |

The inner electrode for MLCC etc… |

| NP-9000 (Base metal Pastes) |

Al, Ni, Cu pastes etc… Possible to use as the electrode of various electric devices. |

| D series (MO Pastes) |

The electrode for thermal head and Bonding Pat etc… |

Dielectric Pastes  |

| NP-7000 (Glass Pastes) |

Possible to use as the protection film and the marking, the dielectric film, the transparent dielectric of various electric devices. |

Ag Paste of next generation

NP-4300 series

The termination electrode for MLCC and Chip components etc…

- Superior in soldering, to make no-plating become applicable.

- Superior in adhesives with a substrate.

- Simultaneous firing with inner electrode is possible.

Conductive Pastes  |

|

Article No.

|

NP-4320 |

| Viscosity |

Can be set up as will |

| Recommendable conditions |

Formation conditions |

Dipping or Printing |

| Drying |

170-185℃x10-15min |

| Firing temp. |

780-850℃(Top Keep:10-15min) |

| Firing time |

60min |

NP-4100 series

The inner electrode for MLCC and Chip components etc…

- Matching with ceramics is good. (The shrinkage curve can be set up as will.)

- Heat resistance to make the firing at 950℃ become possible.(To substitute Ag/Pd becomes possible.)

- Low resistance can be kept even under high temperature.

- It is possible to form the fine of L/S=40/40μm at screen printing.

Characteristic table:

|

Article No.

|

NP-4125A NP-4125A

|

NP-4125A1 NP-4125A1

|

NP-4125B1 NP-4125B1

|

NP-4125C1 NP-4125C1

|

NP-4125D1 NP-4125D1

|

|

Viscosity

|

Can be set up as will

|

|

Recommendable conditions

|

Mesh

|

SUS#200-325

|

|

Drying

|

70 ℃ ~x5min

|

|

Firing temp.

|

850~920 ℃

|

|

Printing thickness/Firing thickness

|

20~30μm/13~20μm

|

|

Sheetresistance(mΩ900 ℃ )

|

2

|

2

|

2

|

4

|

7

|

|

Firing shrinkage(%:900 ℃ )

|

15

|

14

|

8

|

4

|

2

|

Pt Paste NP-1000 Series

- By high precise nature, it is possible to form continuation film even at least below 1μm.

- By selection of the bonding, it is possible to correspond

- By selection of powder and adding of sintering-control agents, it is possible to correspond to the firing at 1000~1500 ℃ . (Simultaneous firing with ceramics is possible)

- It is possible to make patterning of 50μm line at screen-printing.

| |

PT-021 PT-021

|

PT-050 PT-050

|

PT-081 PT-081

|

|

Surface area(m 2 /g)

|

2.4

|

1.0

|

0.9

|

|

Particle diameter(μm)

|

0.2

|

0.6

|

0.8

|

|

Tap density(g/cc)

|

4.0-4.5

|

6.5-7.5

|

6.5-7.5

|

|

Heat resistance

|

Average

|

Good

|

Best

|

|

Dispersion

|

Average

|

Good

|

Best

|

|

Thin layer

|

Best

|

Good

|

Best

|

|